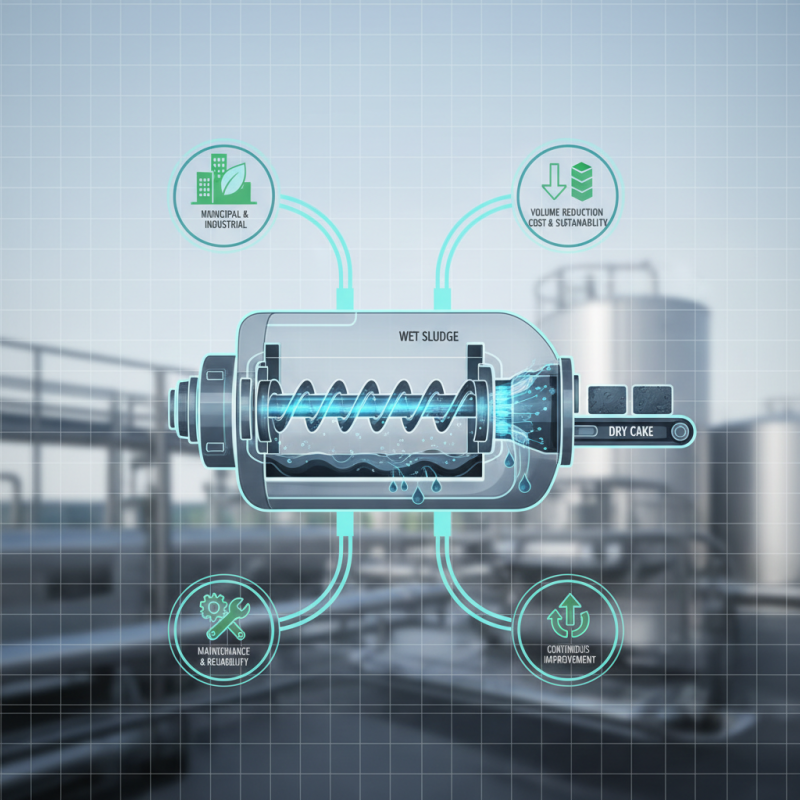

In 2026, the need for efficient wastewater management has never been greater. A crucial tool in this process is the Sludge Press. This machine transforms wet sludge into dry cake, reducing waste volume significantly. The technology has evolved rapidly, introducing new features and capabilities.

Modern Sludge Presses employ advanced mechanisms to optimize performance. They can operate in various settings, from municipal plants to industrial facilities. As cities grow, managing sludge becomes a complex task. The Sludge Press plays a key role in minimizing environmental impact. It offers a solution for both cost reduction and sustainability.

However, users must consider some challenges. Maintenance of the Sludge Press is essential to ensure efficiency. Regular checks can help prevent costly breakdowns. It's important to remember that no technology is flawless. Continuous improvement and adaptation are necessary to meet changing demands. Understanding the Sludge Press is vital for anyone involved in wastewater treatment.

A sludge press is an essential tool in managing wastewater treatment systems. It separates liquid from solid waste, reducing the volume of sludge. This process is crucial for recycling and disposal efforts. In 2026, advancements in technology have improved its efficiency significantly. More precise mechanisms are now in play, ensuring better output quality.

The functionality of a sludge press involves several intricate stages. Waste is fed into the press, where hydraulic force helps squeeze out moisture. This process results in a dry sludge cake. The remaining liquid, often referred to as filtrate, can be treated further or safely disposed of. Operators must remain vigilant, as overloading or improper adjustments can lead to inefficiencies.

Despite the progress, challenges exist. Some sludge presses may have difficulty processing certain types of waste, especially those with high fibrous content. Regular maintenance is necessary to ensure optimal performance. Users must also assess output quality frequently. Inconsistent results can complicate disposal processes and lead to increased costs. Addressing these issues continuously can enhance overall system efficiency.

| Feature | Description | Functionality | Efficiency (%) |

|---|---|---|---|

| Type | Belt Filter Press | Separates solids from liquids | 80 |

| Capacity | Up to 20 tons of sludge per hour | Handles large volumes efficiently | 85 |

| Operation | Continuous operation | Suitable for various industries | 90 |

| Maintenance | Low maintenance requirements | Cost-effective | 95 |

| Output Quality | Dry solids | High-quality cake for disposal | 92 |

A sludge press is an essential tool for wastewater treatment. In 2026, it plays a crucial role in managing waste efficiently. The key components of a sludge press system include the feed system, pressure chamber, and filtrate collection area.

The feed system introduces sludge into the press. It often uses a pump or conveyor. This component must work reliably. Otherwise, it could cause delays. Once in the pressure chamber, sludge is compressed. Pressure is applied to remove excess water. This step is vital. It enhances the concentration of solids. The pressure might not always be enough. This inconsistency can lead to varying results.

Filtrate collection is another critical component. It gathers the liquid expelled from the sludge. This process needs careful monitoring. Any leakage could compromise effectiveness. Sludge press systems often face challenges. Maintenance is essential to keep all parts functioning. Regular checks can prevent major breakdowns. Understanding these components is vital for optimizing sludge management. Each piece plays a role in achieving better treatment outcomes.

In 2026, the sludge press remains essential in wastewater treatment. Its main goal is to reduce water content in sludge. This helps in managing waste more effectively. Sludge is collected from various processes. The thickened sludge then enters the press for dewatering.

The operational process begins with feeding the sludge into the machine. It travels through a series of chambers. Pressure is applied gradually. This pressure forces the water out, leaving behind a solid mass. Operators monitor the pressure and flow rates closely. Adjustments may be necessary to optimize performance. Sometimes, too much pressure can damage the material. Finding the right balance is crucial.

After dewatering, the resulting cake is removed. At this stage, it can be used for composting or disposal. However, challenges remain. The quality of sludge can vary. Not all sludge can be processed effectively. Operators often need to evaluate the input material. Ongoing training and innovation play vital roles in improving the process. The industry is constantly evolving, seeking more efficient methods.

The advancements in sludge press technology have revolutionized wastewater management. In 2026, these machines are more efficient and compact. They can handle a wider range of materials with minimal energy consumption. Enhanced automation features also streamline operations, making processes faster and more reliable.

One noteworthy development is the integration of smart sensors. These sensors monitor moisture levels and adjust pressure accordingly. This real-time data helps in optimizing performance. However, this technology can sometimes be too sensitive, leading to inconsistencies. Operators must regularly check and calibrate these sensors to maintain efficiency.

Tips: Regular maintenance is key. Check the pressure gauge and clean filters often. Keeping equipment in top shape prevents unnecessary downtime. The new designs may look sleek, but they often come with hidden complexities. Understanding these nuances is crucial for effective operation.

Sludge presses play a critical role in waste management. These machines efficiently dewater sludge, reducing its volume and weight. Research shows that proper sludge handling can cut disposal costs by up to 50%. The process involves pressing moisture out of the sludge using high pressure. This results in dryer, more manageable waste. The outcome can lead to easier transportation and lower landfill fees.

Many industries utilize sludge presses. Municipalities often rely on them for wastewater treatment facilities. In 2026, approximately 45% of sludge generated in urban areas is processed through these systems. By reducing liquid content, sludge presses can convert waste into products like biofuel. The benefits extend beyond cost savings. They also contribute to environmental sustainability by minimizing waste disposal impacts.

Despite these advantages, challenges remain. Not all sludge presses achieve ideal dewatering levels. Some may leave behind excess moisture, which complicates disposal. Furthermore, maintenance costs can accumulate over time. It is essential for operators to monitor performance closely. Improvement in technologies may address these shortcomings. The overall effectiveness of sludge presses continues to evolve, reflecting ongoing innovation in waste management.

2025 Bio-Botanica, a division of Bio Answer Holdings Inc. All Rights Reserved.